Custom Quote Request Form

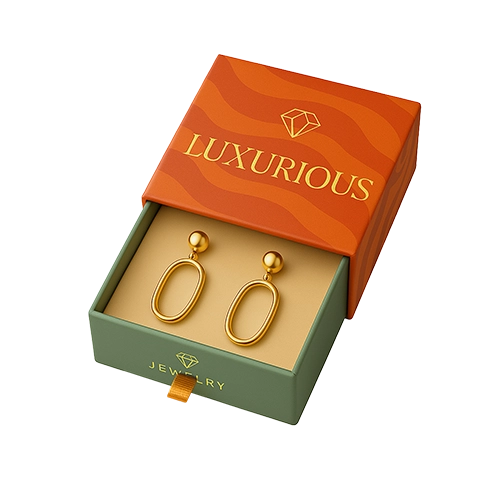

Book Style Boxes

FAQ'sSpecification Learn More Reviews |

||||||||||||||||

|

Q: What are book style boxes? A: Book style boxes have a simple and structurally strong design and open like a book. Q: What material and thickness is used for manufacturing custom book boxes? A: Premium quality cardboard is used for manufacturing book boxes. The thickness of the cardboard varies and can be adjusted to fit your specific requirements. Q: Are book style boxes shipped assembled? A: Yes, branded book style boxes are shipped assembled and ready to use. Q: Can book style boxes have a window cut-out? A: Yes, custom book style boxes can have a window cut-out. Additionally, a clear PVC sheet can also be added on to the window cut-out area.

Sustainable Materials for Custom Book Style Boxes: An OverviewBook-style rigid boxes can be used to display and package high-value products such as electronics,toys, and personal care items. The defining characteristic of this type of box is the top flap thatopens up in a way similar to opening a book. These boxes are typically made from high-quality cardboard or rigid paperboard. These boxes are designed to be durable and provide a secure fit for the item being stored. In addition to featuring a lid that can be opened and closed, these boxesmay also include handles for easy carrying. Custom book-style boxes can be made from several materials, including:

Choosing the right material thickness for your custom book-style box is essential for protecting the enclosedproducts during shipping and ensuring the box is durable and long-lasting. Consider the following factors when choosing the material thickness and type for book-style boxes:

Keep a balance between the cost, protection, and branding impact of the box when choosing the right thickness. You can work with a packaging expert or manufacturer to determine the optimal thickness for your needs. |